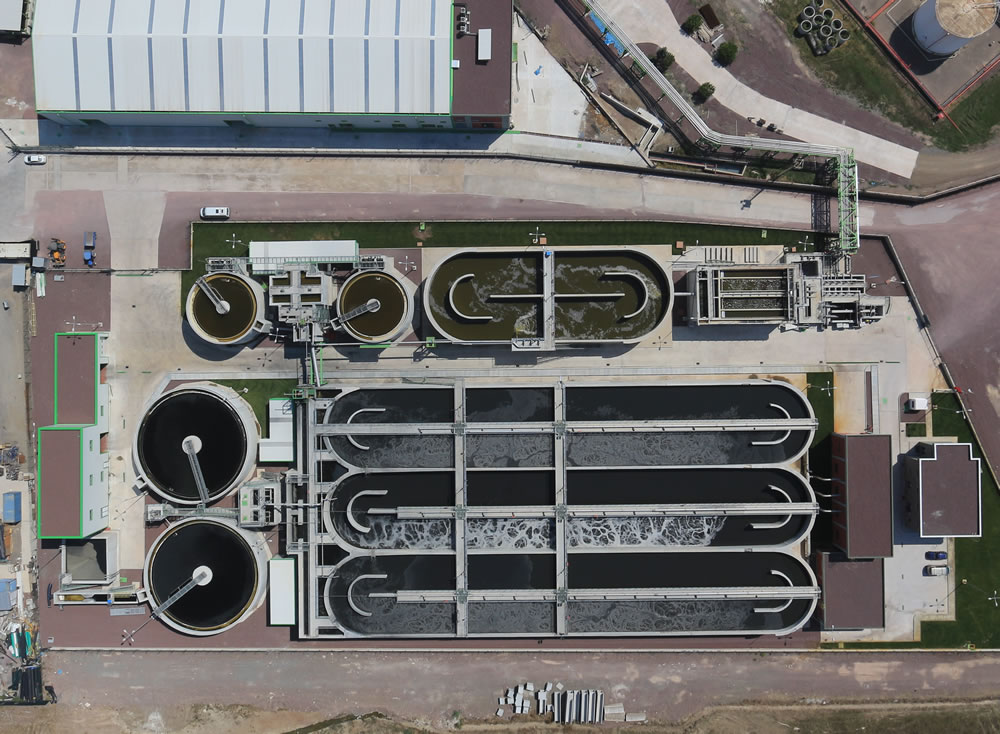

ACTIVITIES

Industrial Wastewater

Industries’ versatility causes wastewaters to be in different character. Because of this, in every application, there is a custom solution development needed for the contamination problem peculiar to an industrial plant. ENTA Engineering grounds on its distinctive solutions, relations of production/use of water/wastewater formation in the plant, wastewater characteristics, refinable features and local conditions.

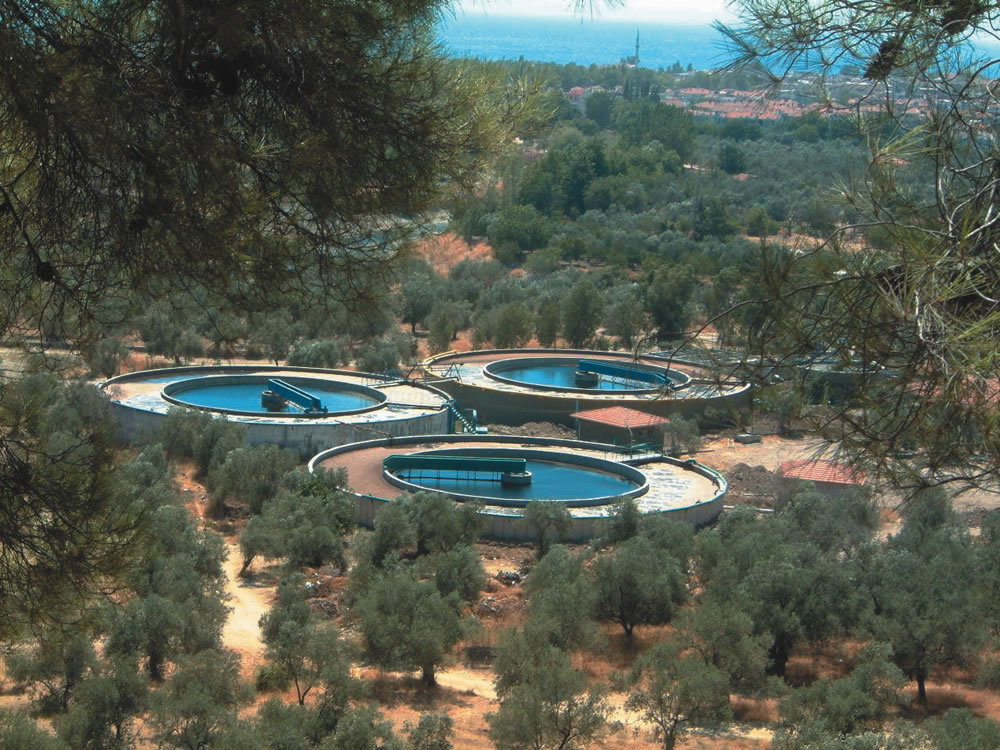

Domestic Wastewater

ENTA Engineering offers service for all domestic wastewater purification caused by hotels, towns and settlements of all sizes, ranging from city and consultancy to establish turn-key plants for all contexts. ENTA also produces necessary electromechanical systems, mounting and operation for these type of plants. In all facilities where ENTA Engineering has been established, treatment efficiencies related to environmental laws have been provided consistently. In case of necessity, it is also possible to use purified water for irrigation purposes.

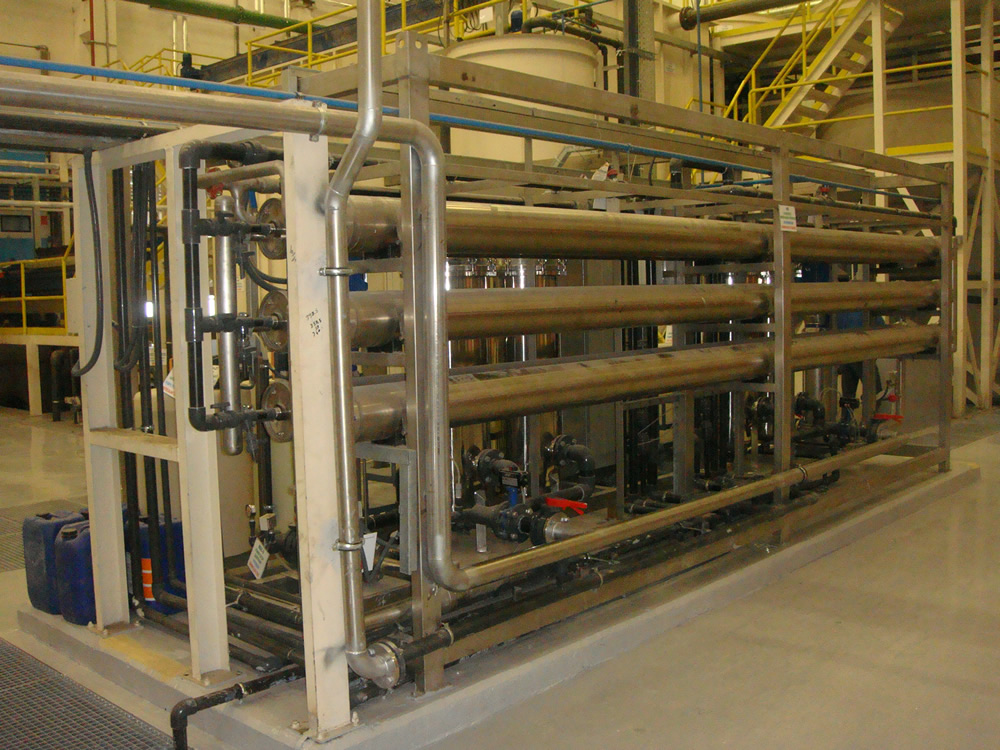

Water Treatment / Water Recovery

According to the quality of water for domestic and industrial water use; Designs are carried out according to flocculation / coagulation, simple and lamella precipitation, sand filtration, removal of iron and manganese (oxidation), ion exchange, activated carbon adsorption, chlorination, ozonation and ultraviolet methods. With the increasing usage of membrane technologies, advanced treatment of water is realized by economical and ecological solutions produced from increasing use of membrane technology. Reverse Osmosis (Reverse Osmosis), Ultrafiltration, Nanofiltration etc. The design, supply and application of the systems are carried out by our dynamic, meticulous and expert staff.

Manufacturing and Equipment Supply

The efficiency of water purification plant depends on the use of well-designed, good quality mechanical equipment. For the production of mechanical equipment, ENTA has an environmentally compatible production and produce in accordance with the norm such as TSE, DIN, BS, CE etc. ENTA’s production program equipment include; automatic screen, screen presses, grit separators, static sieves, mixers, fixed and rotating bridge scrapers, oil separators, DAF units, surface and pressured filters, clean water equipments, steel tanks, silo, weirs, concentrators, deflectors, conveyor, container and sludge dewatering equipments.

Design and Consultancy

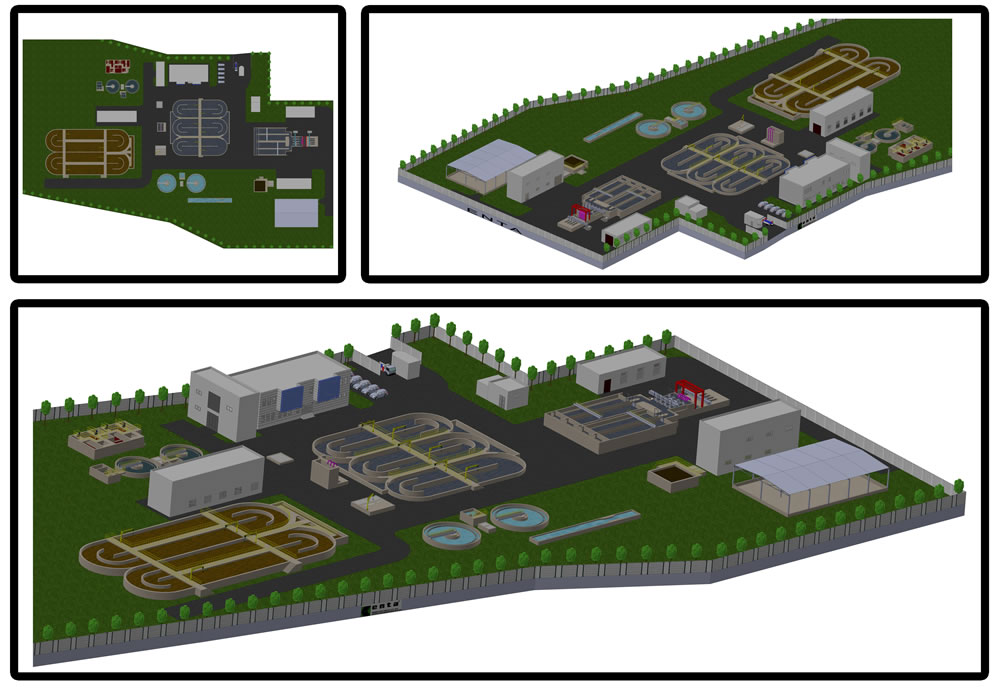

Having completed nearly 500 projects so far both in Turkey and 29 countries in the world with its expert staff who are well-experienced and open to new technologies, in addition to commitment works, Enta has been also accredited by The Ministry of Environment and Urbanization for Municipal and The Ministry of Industry and Technology has numerous projects that have been granted a visa which industrial and water treatment plant project design with its’ project coordinators and competent engineering staff.

With a project flow rate 200,000 m3/day, Velimese OSB Industrial and domestic wastewater treatment plant will have the largest water treatment plant in the Turkey’s organized industrial zone when it is completed.

We have also completed and validated Iraq/Najaf City Wastewater Treatment Plant with a project flow rate 100,000 m3/day, Iraq/Al Numania City Drinking Water with a project flow rate 158,000 m3/day and some of the town project work in Iraq with a 1000 m3/hr capacity.

Operation and Maintenance

It is our goal to give you the best and fastest service in case a malfunction that may occur after our project design, start up and delivering of the project to our customers.

Nowadays, the most neglected issue is the maintenance and operation of water and wastewater purification plants. Enta Engineering, upon receiving the necessary commitment, takes the annual operation and mechanical care responsibility of these plants. And by this way, extends the life of the system, prevents envirmental and economic losses. Enta Engineering shows its’ experience by taking the plants’ operation/maintenance jobs.

With the meticulous and expert technical staff, Enta Engineering completes the given work precisely and perfectly during the performance of maintenance works. As with all other activity in developing areas, Enta continues its work by enabling its staff in adopting the best benefit from emerging technology/information, increasing business efficiency and system protection.

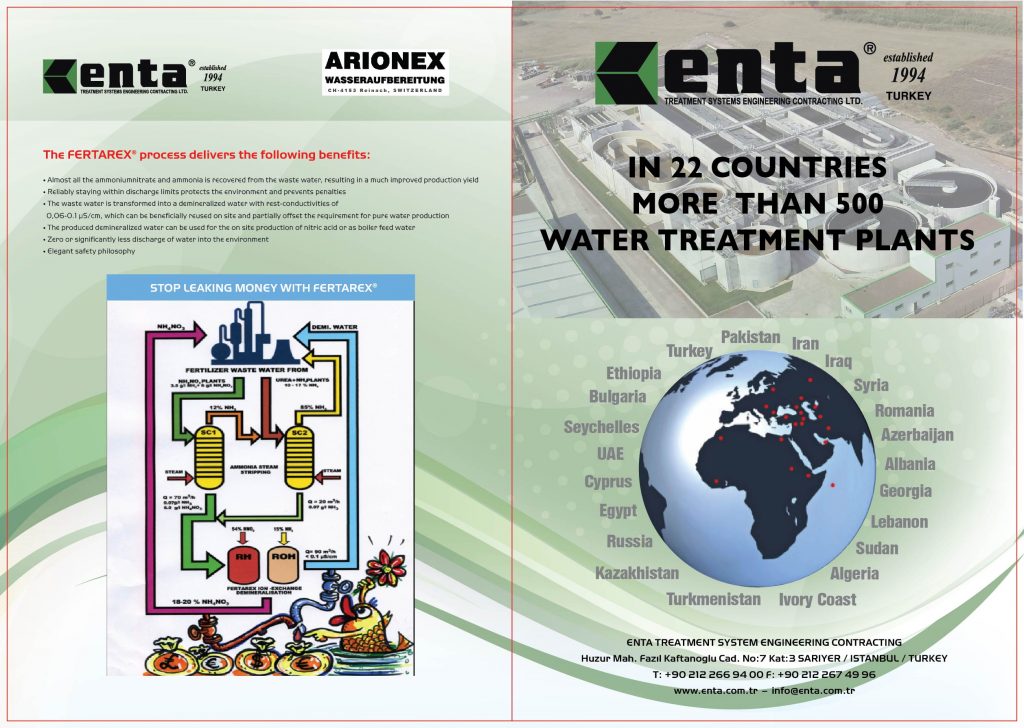

Fertarex Wastewater Treatment & An Recovery Plant

The discharge of N-NH4 and N-NO3 into the environment is harmful the fertilizers enhance growth of algae and bacteria in natural water bodies. Input of nutrients into the water above a natural balanced level causes so called, eutrophication of the water body and can result in fish kill and a loss of biodiversity.

There have been several attempts already to clean this type of waste water e.g by means of biological treatment methods. But it was found that this method is very costly since with conventional nitrification / denitrification huge amounts of organic material have to be dosed to the waste water to feed the micro organisms with a carbon source. In addition to that nitrogen feed concentrations are relatively high. As a result it is very difficult to accomplish emission limits of 1.5 mg/L N-NH3 to 10 mg/ L N-N03: This would equal a removal rate of 95 % and more, which would mean at least a multi-stage plant and most likely a polishing step. Hence to rely on biological treatment would mean high costs and resource consumption, and nelther ammonia nor nitrate would be recovered.

A solution for this situation is offered by the so called FERTAREX water treatment process which has been developed by the ‘ARIONEX Wasseraufbereitung’a company that is based in Switzerland. Slx plants of this type have been built in Europe and Asla. The first unit was installed in 1975, and over the last 35 years the economics and reliability of the process has been demonstrated.

The FERTAREX Process Delivers The Following Benefits: